A revolutionary process

This revolutionary process is capable of manufacturing complex geometries regardless of the the object's complexity.

The machine uses a vat of photosensitive epoxy resin liquid which it polymerized by an ulta violet laser. The object is created by successive layers. These layers are stacked one upon the onther at the appropriate rate for creation of the model.

The thicknesses of the layers are managed by the programmer and can range from 50µ à 500µ (usually: 100µ ou 150µ).

The wide range of resins allows for the validation of the concept but it can also be used for the creation of tools. The available epoxy resins, flexible or rigid, are of ABS, PP, EP PBT and ceramics types. A transparent resin and a high-temperature resin (>250° C) complete this range of materials.

In only a few hours this technology is able to produce your models and prototypes by using successive layers.

It's value lies not only in its ability to construct the model in full form but to also allow for the validation of the the concept; the assembly of parts as well as the hinge validation.

High Resolution Stereolithography

This high resolution technology takes over for the more demanding requirement, such as: micro parts, delicate jewellery, ultra-fine inscribing, etc…

Stereolithography Prototype, SLA Prototyping |

|

Stereolithography is the heart of rapid prototyping service, turning your 3D CAD drawing into a solid object. Most stereolithography prototyping can be completed in as little as 1 to 2 days, with larger projects typically completed in under 5 days. Stereolithography prototypes can be used as master patterns for injection molding core and cavity inserts, thermoforming, blow molding, and various metal casting processes. Stereolithography is the heart of rapid prototyping service, turning your 3D CAD drawing into a solid object. Most stereolithography prototyping can be completed in as little as 1 to 2 days, with larger projects typically completed in under 5 days. Stereolithography prototypes can be used as master patterns for injection molding core and cavity inserts, thermoforming, blow molding, and various metal casting processes.

Key benefits of Stereolithography Rapid Prototyping

- Time savings: can fabricate your SLA prototype in less than two days

- Cost savings: prices stereolithography prototypes competitively

- Tight tolerances

- Epoxy resin is resilient enough to be used for testing

- Stereolithography is well suited to small lot manufacturing of prototype or end-use parts

- Stereolithography investment casting patterns allow rapid production of metal prototypes

- Rapid prototyping allows you to get your products to market faster

Technical Overview of Stereolithography Rapid Prototyping

To create an SLA rapid prototype, first a three-dimensional CAD part is "sliced" horizontally into cross-sections between 0.002" and 0.006" thick. The slices are fed to 3D Systems' Stereolithography Apparatus. Inside the stereolithography chamber of the apparatus, an ultraviolet laser traces the first layer of the part on a metal platen, submerged just below the surface of a vat of photo-sensitive polymer. Wherever the laser touches the liquid, it solidifies. Once the layer is traced, the platen sinks the thickness of a layer below the level of the liquid. A sweeper bar moves across the surface of the last layer, making sure there is the exact amount of resin on top. The next layer is then built upon the previous layer. In this manner the entire part is built from the bottom up, with the completed sections of the part remaining submerged.

Stereolithography (SLA) FAQs

- What does SLA mean?

- SLA is an acronym that stands for StereoLithography Apparatus.

- What material does stereolithography rapid prototyping use?

- The resins used in our SLA machines are photosensitive epoxy polymers. uses a variety of stereolithography resins in our machines. WaterShed 11122XC, the resin run in our Viper si2 machines, is untinted and can result in clear prototypes, given a Level 6 finish. The ProtoGen 18420 resin is can be heat treated for higher heat deflection temperatures. The Accura 25 resin is a white polypropylene-like resin designed for flexibility and snap fits. Accura 60 is a tough general purpose resin which can make translucent parts. Please see above for data sheets on these resins.

- What tolerances can the stereolithography process hold?

- Published tolerances of the models are +/-0.005" (0.127mm) for the initial inch, plus an additional 0.002" for each additional inch. If higher accuracy parts are needed, please contact us for a personal evaluation of your project.

- How can I ensure that raised text on my prototype is legible?

- The height of the text should be a minimum of 0.015" high, and the cross section of the text should be 0.015" or thicker. Text thinner than this cannot be reliably traced with the 0.010" thick laser beam. See our guide to raised text on stereolithography prototypes.

- How does price parts?

- The following factors influence pricing:

- Z-axis height

- Volume

- Complexity

- Number of parts

The per-part price decreases as more parts are ordered until the point where there are too many parts to fit on a single run of one of our SLA machines.

- What size parts can be produced?

- largest machine has a build envelope of 20" x 20" x 24"; however, multiple SLA prototypes can be glued together to create larger prototypes. For more on large prototypes.

- What is the smallest feature that can be produced?

- In standard resolution, the minimum feature in the X-Y plane is 0.010" and the minimum in the Z axis is 0.016". In high resolution, the 0.003" laser beam spot enables smaller features. ecommends a minimum wall thickness of 0.020" for prototype support.

- What colors can be produced?

- Stereolithography prototypes can be dyed or painted in virtually any color.

- What kinds of finish options are available on SLA prototypes?

- Finishes range from inexpensive natural parts to fully smoothed and painted show pieces. For more information, check our SLA Finish Levels page.

- What temperatures can SLA prototypes withstand?

- The standard epoxy resin has a heat deflection temperature of 144°F and high temperature epoxy resin has a heat deflection temperature of 392°F.

- Can stereolithography prototypes be machined?

- Yes, SLA prototypes can be drilled and tapped, milled, or put on a lathe.

- Why should you use SLA versus another rapid prototyping technology?

- The accuracy and surface finish of SLA are unsurpassed by any of the competing technologies, such as selective laser sintering (SLS).

- How long does it take to build a part?

- A typical order of prototypes is shipped out two days after receipt of order. Most parts build in less than 12 hours.

|

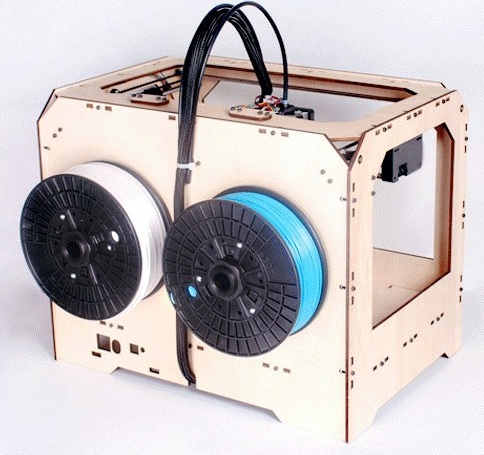

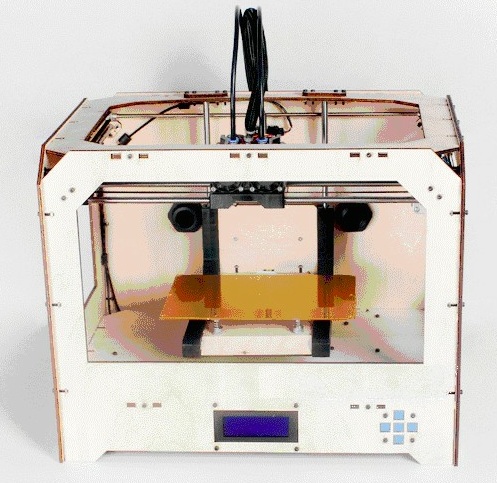

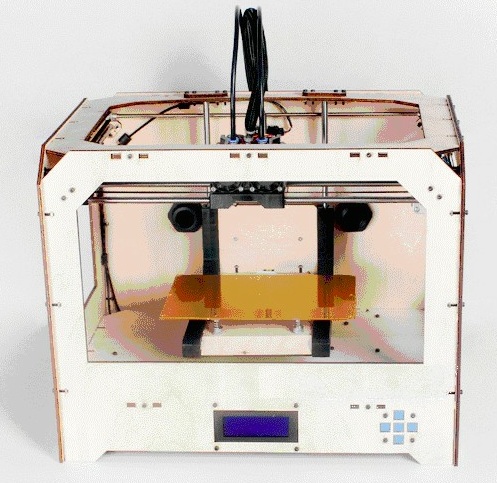

1. Spec

a) size:320*467*381mm

b) weight:15kg

c) printer:2

d) color:original+color

2. Print Spec

a) Print size:225*145*150mm

b) thickness:0.1-0.5mm adjust

c) printer D:0.4mm

d) move speed:40mm/s

e) print speed:24cc/hour

f) temperature:230C

g) max temp of heater: 120C

h) presice:z 0.0025mm,XY 0.012mm

3. Software Spec

a) controller ReplicatorG software

b) OS: Linux, Windows OSX

c) from SD card or usb

d) input fiel: STL,gcode

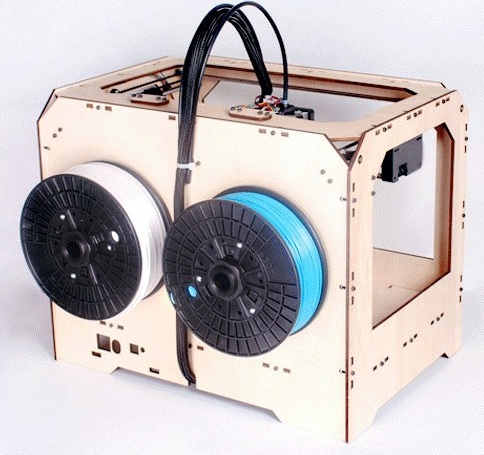

4. Material

a) ABS PLA

b) D: 1.7-1.8mm

Our delivery has mass producing quality assurance. We warrants our products against manufacturing defects for a period of one year from date of shipment to the original purchaser, and offers software updates lifetime to registered customers free of charge. We have an experts team to provide technical support.

We have been running 8 years, this is our license from Chinese government website:

http://www.sgs.gov.cn/LicenceView/Id=20120530152953117

We have served 1000+ customers from 100+ countries all over the world, Please find a list of part of our customers here:

http://www.quickembed.com/Tools/Shop/Customer/Index.html

We can provide contact if you want a reference.

We are looking for sell/retail/ditribute/channel partners in all over the world.

You are encouraged to share your information in the forum, share your business information, share your success, it will get you more business and success!

If you need some partner, technical, hardware, software, marketing, channel, sales, just post your message on the forum, because someone in the world may be finding you!

Our world and technology is changing and growing so fast that no one no single company can do all work, clever people can get information from the web and try to make it but will take a lot time to learn, we need cooperation!

Promote your product in the forum, or just an idea, don't be afraid other will copy, there are similar products and ideas all over the world, the only difference is who will make it real in a right time in success!

If you want more formal, list your product in our web catalog, to promote it to all over world, we are open, please send email to us.

We can build a prototype sample very fast, for you, to demonstrate, to your customer.

A demo is much more powerful than a thousand words!

It will save you a lot of valuable time!

Make a concrete step from good idea to real success!

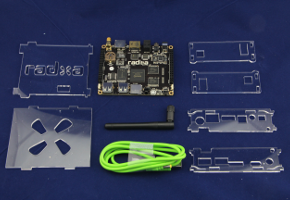

We help you succeed, providing ARM Embedded Quick Demo.

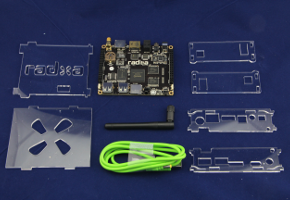

ODM/OEM Service

Layout, for special defined interface and resize the board for your requirements.

Product prototyping, sourcing accessories for your product requirements.

Recommend GPS module, GSM/GPRS module with communication software.

Software Developing.

Sourcing solution and turn key to you.

You might have interest to know what products this board makes, please send us an email to know more product design cases. Embedded pc computer system has broad usge, some examples:

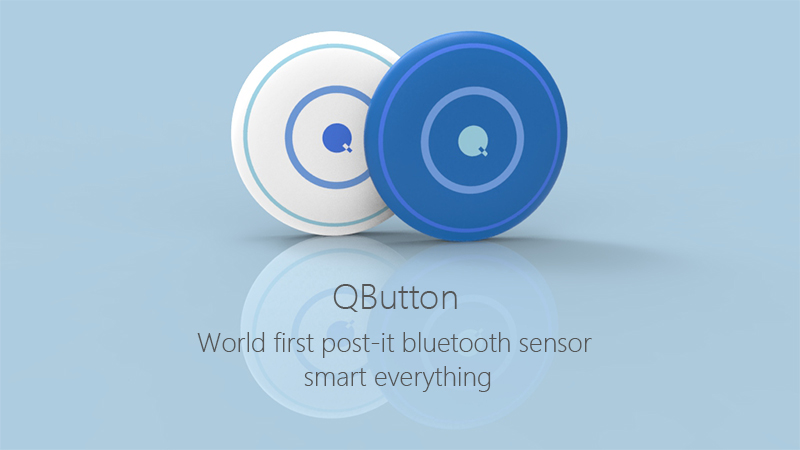

QButton, world first post-it bluetooth sensor, open data, customize for your usage.

Popular bluetooth v4.0 ble sensor tag, smart devices, wearable electronic computer.

Palm size desktop computer.

U-disk size computer

Android 4.0 5inch 7inch capacitive touch pad

9D position pose system digital compass

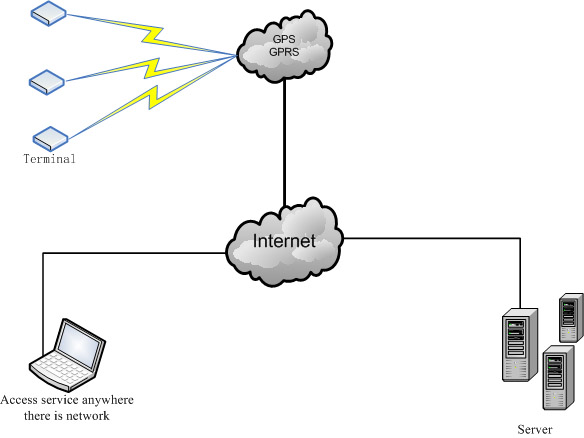

GPS, Compass and accelerator in one tiny module.

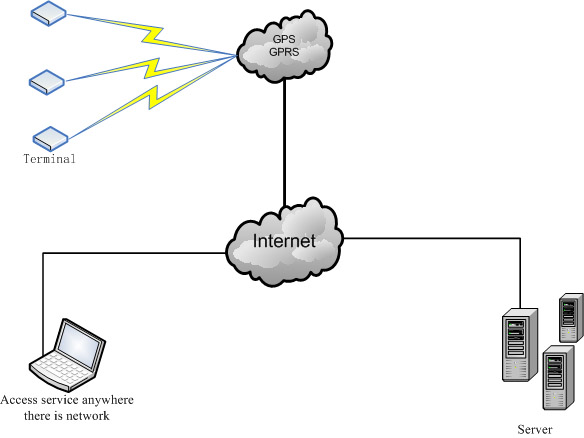

GPS GPRS LBS solution.

Navigate Locate Track Solution, Location Based Service

Robot Motor Medical Testing System

One motor control board controlling 9 motors at the same time

Robot arm move and grab.

12" to 15" size multimedia or HMI solution, fixed on wall or desk or large vehicle:

Backside:

10" solution, fixed in car:

7" solution, fixed in car:

more 7inch cases here:

http://www.quickembed.com/Tools/Shop/Solution/201001/67.html

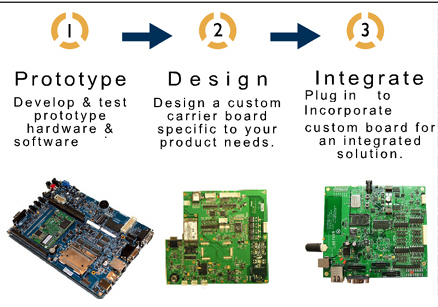

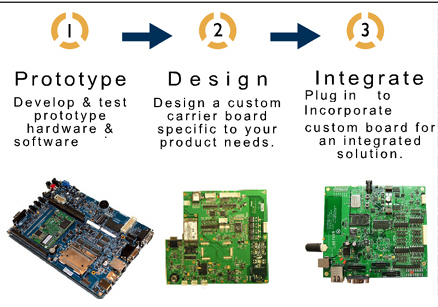

Using SBC is as easy as 1,2,3; simply prototype and test your development using a suitable SBC, then design your custom connector board and finally build your product.

The advantage of SBC is that when you define a new product, you have only small change on baseboard/motherboard, no change on SBC/daughter board, it saves great effort, and save much expense as the SBC is big lots produced while baseboard can be produced in small lots, also this helps improving the quality of your products.

Read more about arm board customize design odm service.

Read more about arm linux driver and application software develope.

Our mission is to provide quick start and easy use embedded platforms for maximize customers productivity. If you find any platform more competitive than ours, please do let us know. We can improve our product for you.

Those who want to list your product here in this web and sell to worldwide customers, please contact us.

-- Stay Hungry. Stay Foolish. Memory of Steve Jobs.

-- Dream bigger, Love Deeper, Live Longer! :-)

|

Stereolithography is the heart of rapid prototyping service, turning your 3D CAD drawing into a solid object. Most stereolithography prototyping can be completed in as little as 1 to 2 days, with larger projects typically completed in under 5 days. Stereolithography prototypes can be used as master patterns for injection molding core and cavity inserts, thermoforming, blow molding, and various metal casting processes.

Stereolithography is the heart of rapid prototyping service, turning your 3D CAD drawing into a solid object. Most stereolithography prototyping can be completed in as little as 1 to 2 days, with larger projects typically completed in under 5 days. Stereolithography prototypes can be used as master patterns for injection molding core and cavity inserts, thermoforming, blow molding, and various metal casting processes.